How to design a car (part eight): aerodynamics

The science of aerodynamics has long helped shape the cars we drive, but what effect do drag, downforce and lift actually have on road cars?

Curiously, we hear less about aerodynamic performance in the 2020s than we did a decade or so ago. In the 1980s, Audi even went through a period of proudly printing the Cd, or drag factor, on the rear side glass of its 100 and 200 models (0.30) and it was a reasonably accurate and reliable figure. Maybe motor companies are now reluctant to give out figures because they are mostly so appalling.

When you think how early philosophers correctly developed theories about the properties of air when it could not be seen, smelled or tasted, you realise what a giant leap in our quest to understand our environment that was. Unlike religion or superstition, you could see the effects of the wind or feel it on your face, even if your eyes told you that there was nothing there. As far back as 350 BC, Aristotle observed that air must have weight. By 250 BC, Archimedes refined this hypothesis, stating that every point on the surface of a body either immersed in a fluid or air was subjected to a force applied by the fluid. We know that by 1490 Leonardo da Vinci had begun a study of the flight of birds; following Archimedes’ theories, he also studied the effect of water in a stream flowing past an object placed in it. His drawings of the disturbed water flow look remarkably similar to modern-day Computational Fluid Dynamics.

> How to design a car (part two): front grilles

It was the 18th century Dutch scientist Daniel Bernoulli who brought discipline and calculations to the relationship between pressure and velocity in moving liquids. He demonstrated that when a fluid passes through a narrowing section of a circular tube, the speed of the fluid increases but its pressure decreases. It is from this research that the aircraft wing was eventually developed and, more recently, aerodynamic downforce achieved from both the underbody of a car and inverted aeronautical wing forms mounted above the body.

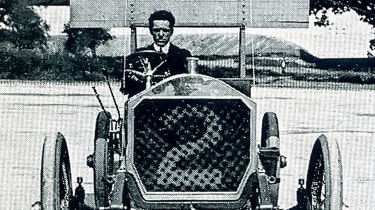

Thanks to the foresight of wealthy visionary HF Locke-King, who built the Brooklands race track and aerodrome in 1907, the British automobile industry had somewhere to test and develop its products. One of the first aerodynamic studies applied to road, as opposed to race, cars was carried out there by the Napier company’s chief engineer, SF Edge, to measure the effect of ‘wind drag’ on speed, fuel consumption and power required for different size closed car bodies. This was important work because, whatever the drag coefficient, it is meaningless on its own; it needs to be multiplied by the frontal area of the vehicle in order to be comparable with another vehicle. For example, a single-deck and a double-deck bus may have the same drag coefficient, for example 0.40, but the frontal area of the double-decker may be 12 sq m, while that of the smaller bus would be 6 sq m and will therefore need only half the power to achieve 60mph despite having that same Cd.

The building of Germany’s autobahns in the ’30s was instrumental in radically new aerodynamic forms coming from European manufactures such as Porsche, Tatra, Audi (then Auto Union) and occasionally Mercedes. However, the emphasis was always on reducing drag. What we know is that any reduction in drag (wind resistance) will either increase the top speed or reduce the energy consumption. But aerodynamic stability is important for a vehicle’s safety and careful aerodynamic development can also reduce wind noise, reduce the deposit of road dirt, and improve cabin ventilation and cooling efficiency.

The problem with quoting Cd, or drag coefficient figures, is that different wind tunnels around the world can produce different results. None truly represents the actual conditions that an automobile encounters when driving along the road. Early wind tunnels had a stationary floor with the scale model car suspended just above it; more recently, moving belt floors, travelling at the same speed as the wind, attempt to more accurately represent driving conditions.

In some full-size tunnels it is possible to rotate a section of the floor so the effects of side winds can be evaluated. This is something I always do; a rally car, for example, almost always travels slightly or massively sideways relative to its direction of travel, therefore much of our testing with the Prodrive Subaru WRC cars was done at 14 degrees! We also developed wings and splitters both with the car on the ground and half a metre in the air to ensure it flew ‘straight and level’ and did not land either nose first (risking a forward somersault) or tail first (risking being unable to steer).

The thing that has to be considered when developing a fast car is that the effect of the aerodynamic drag of a car is not linear. The amount of energy needed to move it through the air at 50mph will be four times as much for the same vehicle to achieve 100mph. Therefore if a vehicle needs 40bhp to run at 50mph it will require 160bhp to run at 100mph and 640bhp to achieve 200mph. This explains a lot about claimed top speeds and claimed engine power.

When I arrived at Lotus and was asked to redesign the Esprit, the publicity material for the current car claimed a drag coefficient of 0.33. I decided to test that car in the wind tunnel and found that the actual figure was 0.424. This was a problem since despite my best efforts I could only get the new model down to 0.336, which the marketing people had a real problem with. The frontal area was a little lower which, combined with the actual drag reduction, improved top speed from 133mph to 152mph.

This was around the time that Neil Kinnock had a very large accident in an early version of the Ford Sierra on the UK’s M4 motorway. The car was shown to have very poor stability in side winds and Ford’s quick fix was to quietly introduce little protruding ears at the back edge of the rearmost side windows. The problem was that the air needed to break away cleanly as it curved around the ‘D’ pillars rather that develop a big turbulent wake and the ears allowed just that. An early version of the Audi A4 C5 had a similar problem; it later transpired that the car had never been near a wind tunnel; same for the first TT.

There was a time not so long ago when some magazines eagerly printed excited reviews quoting how much downforce had been increased on the latest model of one or another of a company’s sports cars. Very few road cars have any kind of significant downforce, and, just like aerodynamic drag, lift is a function of the square of the speed. To claim a figure for downforce for any road car without stating at what speed that was measured is therefore nonsense.

For a road car, it is better to produce a car with good aero balance, either lift or downforce; putting the centre of downforce near the centre of gravity is a good start. Too much downforce at high speed without very sophisticated rising-rate suspension can mean that the springs have to be so stiff that the thing can ride like a pick-up truck.

It is easy to be taken in by race car downforce and compare it with a road car. For example, a proper GT3 race car produces about 1000kg of downforce at around 130mph, while a 911 GT3 RS is claimed to produce 350kg at 186mph. But since few people corner their road car at those kind of speeds and if we take a more realistic speed of 100mph, that is about 180kg, and at 130mph just 250kg. A recent F1 car might make as much as 3000kg at 200mph. If we sorted the driver’s blood flow and the engine’s fuel and oil flow, they genuinely could drive along the roof of a tunnel.

With a modern SUV weighing 2.5 tons and with a frontal area of nearly 3.8 sq m, drag hardly matters and either lift or downforce becomes irrelevant. But the inefficiency is hideous! For a nimble little sports car like the Alpine A110 it matters a lot. A Cd of 0.32 and drag area (CdA) of just 1.94 sq m, plus 190kg of downforce at 150mph – or 330kg for the new A110S – is rather impressive. With such a comparatively light car (just 1114kg), that extra 140kg of downforce for the A110 S would really be felt, and that is what really matters.